With metal additive simulation powered by Netfabb’s simulation technology, you can evaluate your designs and the numerous variables involved in metal additive manufacturing before sending a job to the printer. By contrast, automated data management using Fusion 360’s Manage extension can be up and running in less than three seconds.Īdditive Simulation Extension (Available January) – Metal additive manufacturing can be time consuming and expensive. Traditionally, data management can take weeks to deploy and requires costly setup.

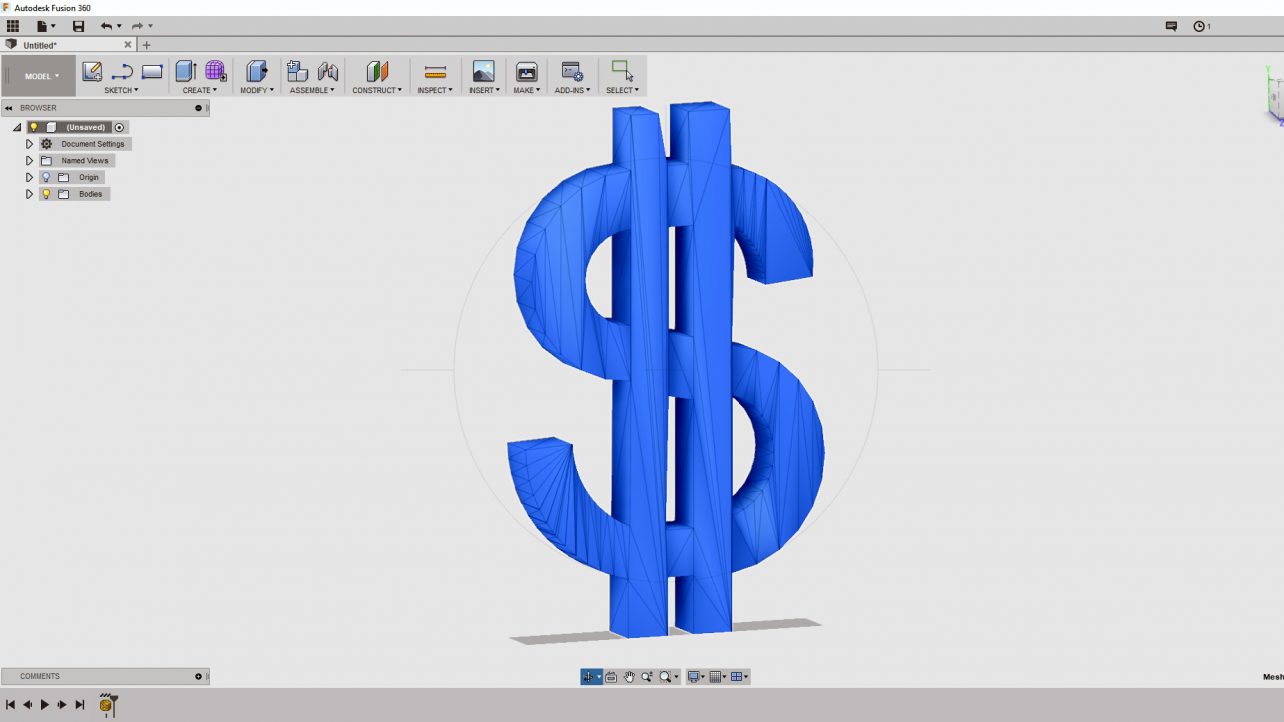

Automatic part numbers, ECOs, process workflows and more will improve the efficiency of your team. Manage Extension (Available January) – To support teams that are standardizing on Fusion 360 for engineering, more sophisticated product data and lifecycle management (PDM/PLM) functionality will be introduced into Fusion 360. In coming months, exciting new extensions you’ll see include: Powered by Netfabb, this Fusion 360 extension opens up a range of pre-defined additive machines. Customized automatic orientation settings (available for FFF and SLM) and support structures settings (SLM only) can be stored in a template library to be used later in new additive manufacturing setups, making future 3D print preparation a breeze. This powerful technology is now available in Fusion 360 to mainstream designers, and this fall, Fusion 360’s generative capabilities are being expanded with generative fluids, offering an engineer many options to explore that optimize designs for fluid flow, and specifically help minimize pressure drop of the flow while avoiding obstacles.Īdditive Build Extension (Available Now) – Set up, slice, and pack your additive manufacturing design to send to your printer and be manufactured. Generative Design Extension (Available Now) – Generative design, initially used in industry for additive manufacturing, is becoming more broadly applicable across manufacturing.

AUTODESK FUSION FULL

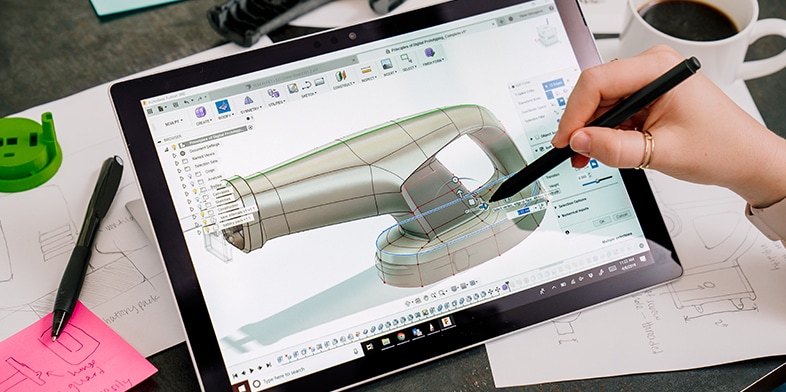

In addition, we are announcing full machine tool simulation for visualizing and verifying CNC programming to help achieve accurate results up front and avoid costly downstream mistakes during machining. This year we announced toolpath trimming and multi-axis collision avoidance inspired by technology from PowerMill. Get advanced, multi-axis toolpath strategies, toolpath optimization, and automated programming to reduce programming time, increase control over your machine, and improve the effectiveness of your NC programs. Machining Extension (Available Now) – Boost the core CAM capabilities of Fusion 360 with this extension. As our annual conference, Autodesk University, kicks off, we think it a great opportunity to recap a few of the highlights we’ve released in recent months, and provide a preview of what’s on the roadmap for the next several. More are coming soon to further streamline collaboration, introduce even greater efficiency into design, simulation and materials usage, and give designers, engineers and manufacturers the ability to achieve the new possible. We’re working to provide designers, engineers and manufacturers the power to focus on innovating, rather than iterating and have recently added several extensions to Fusion 360 that make the platform astonishingly, excitingly capable. Fusion 360 brings design and manufacturing together as a unified experience, which is something we’ve been working on for years and are excited to see industry leaders adopting.

“Digital transformation,” the process of transitioning an entire manufacturing business (or the industry itself) into a digital-first mindset and process, and having all the tools, infrastructure, modified workflows, and capabilities in place to do so, is a gargantuan order. Transforming an existing business–changing how it produces its products, delivers its services, its back-office processes, and culture–is a tall order.

0 kommentar(er)

0 kommentar(er)